Overview

The objective of the Minimum Viable Product was to digitise the product logic of precast lattice floors and to automate its application within projects. This significantly reduced design time, enabled rapid exploration of design options, improved decision-making, and streamlined the tender process.

By achieving these objectives, Laing O'Rourke aimed to gain better control over their design authoring phases, enhance data inputs and information handovers, and ultimately improve efficiency and reduce risks throughout their projects

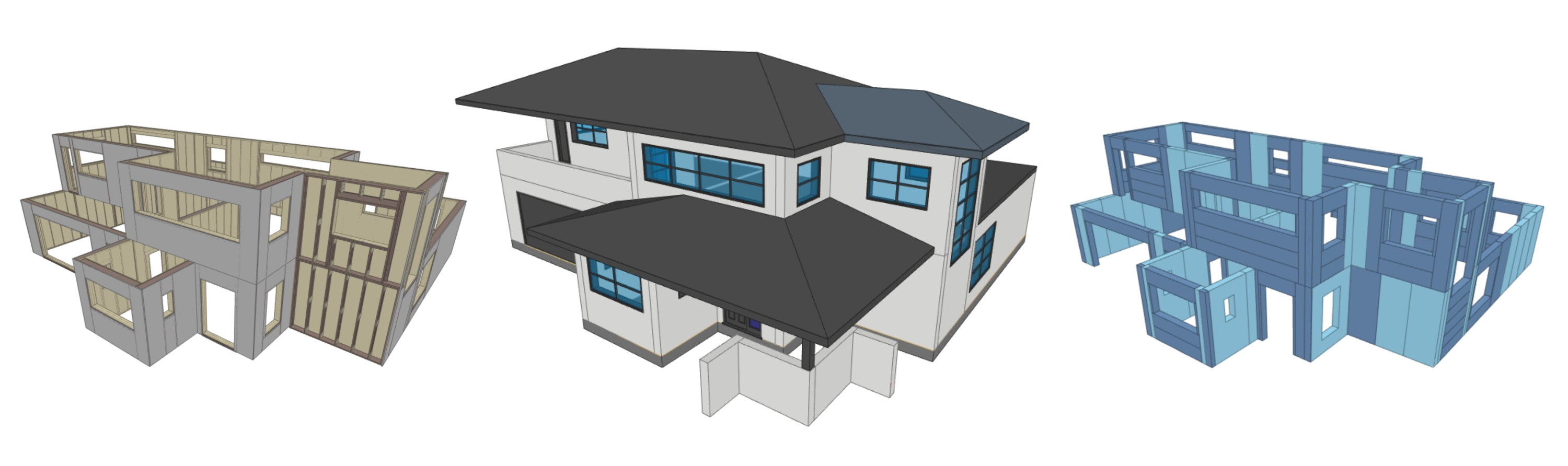

In addition to this a 3D design file was ingested, applied the Laing O'Rourke lattice floor product, analysing and assessing, and then exporting an optimised solution with automated drawings and schedules.

What we did

To initiate the project, KOPE conducted a series of workshops aimed at gathering information, gaining a deep understanding of the existing processes, and identifying the challenges and requirements essential to establish key features and priorities. The primary focus of our efforts was to capture the intricate system logic inherent in precast lattice slabs, while meticulously defining the associated rules and constraints.

%20(2).png)

Our team collaborated closely with Laing O'Rourke's product experts, capturing the system logic in an algorithm. This algorithm encompassed manufacturing capabilities, project-driven constraints, and intricate relationships between building elements, including walls, columns, and slab edges. By accurately capturing these relationships, the algorithm determined how the precast lattice floor panels would interact with other elements within the building, leading to accurate and reliable design outcomes.

KOPE captured the manufacturing constraints, ensuring accurate representation and adherence to manufacturing capabilities. In addition, KOPE identified additional project-driven constraints specific to a particular project, imposed further limitations on the design, and required adaptation. By incorporating these constraints into the algorithm, we ensured it could optimise solutions based on specific project requirements, such as the need for smaller panels due to logistical challenges onsite.

To achieve optimisation, KOPE captured design strategies that identified variables and objectives. Variables, such as panel sizes, and component types, are those that can be manipulated within the algorithm. These were then captured with objectives such as minimizing the number of panel types, or reducing the overall number of parts. By defining these variables and objectives, the KOPE team were able to streamline the design process for Laing O'Rourke, aiming for the most efficient and constructible solutions within the given constraints.

%20(13).png)

Throughout the iterative development process, our agile approach facilitated rapid iterations and progress updates. Close collaboration with the Laing O'Rourke's team ensured that the solution was robust and reliable.

%20(1).png)

The results

The successful integration of the product logic into KOPE's digital platform marked a significant milestone. It enhanced the accuracy, reliability, and efficiency of the design process, empowering Laing O'Rourke to confidently navigate complex projects and optimise constructability.

%20(1).png)